Pipeline Welding Inspection: Protecting Pipelines with Accuracy and Experience

Wiki Article

Advanced Methods in Pipeline Welding Assessment: Developments and Technologies for Improved Accuracy and Integrity in Weld Assessment

The landscape of pipeline welding inspection is undergoing a considerable improvement, driven by innovative strategies that promise to improve both precision and reliability in weld analyses. Developments such as automated inspection systems and progressed imaging innovations are redefining typical methods, while non-destructive screening techniques make certain product stability is maintained. As these modern technologies evolve, they not only boost defect detection rates however also allow more reliable upkeep approaches. Nonetheless, the implications of these improvements extend beyond instant advantages, elevating vital inquiries regarding future techniques and criteria in the industry.

Value of Weld Inspection

Making certain the honesty of pipeline welds is important to the overall safety and security and reliability of industrial systems. Extensive inspection of welds is essential to the lifecycle of pipe infrastructure.The value of weld examination extends past mere conformity with regulative requirements. It functions as an aggressive measure to recognize and remedy blemishes, such as incomplete fusion, porosity, or cracks, prior to they intensify into severe concerns. Effective evaluation techniques likewise add to the long life of pipes, lowering maintenance costs and boosting functional efficiency.

In addition, comprehensive weld evaluations foster trust fund among stakeholders, consisting of governing bodies, capitalists, and the neighborhoods offered by these pipes. By making certain that all welds meet the needed requirements, organizations can alleviate dangers and copyright their reputations. In recap, weld examination is vital not just for functional honesty yet additionally for the wider effects it holds for safety and security and ecological stewardship.

Automated Assessment Systems

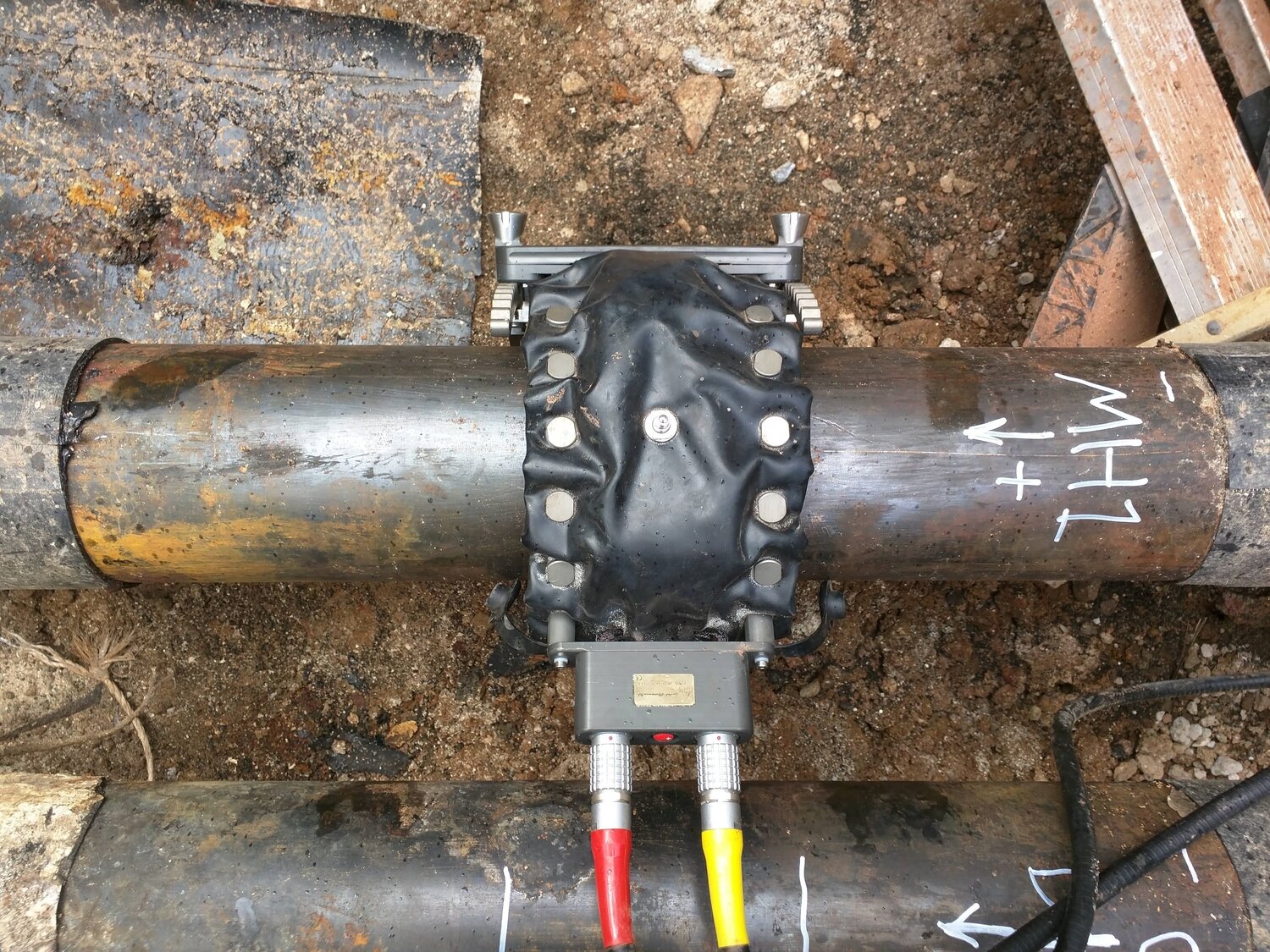

The integration of computerized inspection systems in pipeline welding has transformed the strategy to ensuring weld quality and honesty. These systems employ advanced robotics and synthetic knowledge to carry out assessments that are not just quicker but likewise a lot more regular than standard techniques. Automated systems can cover substantial lengths of pipelines effectively, catching information that human inspectors may ignore as a result of exhaustion or ecological conditions.One of the key benefits of automatic inspection systems is their capacity to run in harmful settings, reducing the danger to human assessors. They use numerous non-destructive screening (NDT) techniques, such as ultrasonic screening and magnetic fragment assessment, to evaluate weld stability without compromising the framework. The data collected is processed in real-time, permitting for instant comments and prompt corrective activities when problems are determined.

Furthermore, automated systems assist in the standardization of evaluation procedures, making sure that each weld is assessed versus consistent standards. This not just improves the integrity of outcomes however additionally streamlines conformity with governing standards. As industries remain to focus on safety and security and functional performance, the duty of automated evaluation systems in pipe welding will definitely broaden, leading the way for extra sophisticated high quality assurance techniques.

Advanced Imaging Technologies

Frequently used in modern-day pipeline welding examinations, progressed imaging technologies have actually dramatically enhanced the capacity to detect and assess weld flaws. Techniques such as electronic radiography, computed tomography, and thermographic imaging supply assessors with high-resolution images that disclose sub-surface defects and structural incongruities that may be unnoticeable to the nude eye.This leads to quicker evaluations and enhanced accuracy in identifying essential flaws. Calculated tomography, on the other hand, supplies three-dimensional imaging, making it possible for assessors to picture intricate geometries and analyze the stability of welds from several angles.

Thermographic imaging uses infrared innovation to detect variants in temperature level, recognizing areas of possible weakness or stress and anxiety within the weld. These advanced imaging innovations not just enhance problem discovery rates yet likewise lower the time and sources needed for pipe evaluations. Therefore, they play an important function in keeping pipeline security and integrity, ensuring conformity with sector criteria while decreasing operational risks.

Non-Destructive Evaluating Techniques

Utilizing various methods, non-destructive screening (NDT) techniques are vital in pipeline welding examinations, enabling the assessment of weld integrity without jeopardizing the material's structural integrity. NDT incorporates a series of methods, including ultrasonic testing (UT), radiographic testing (RT), magnetic fragment testing (MT), and dye penetrant testing (PT) Each method has unique advantages and applications relying on the specific needs of the assessment.

Ultrasonic testing uses high-frequency acoustic waves to discover interior flaws, giving exact measurements of weld thickness and integrity. Pipeline Welding Inspection. Radiographic screening utilizes X-rays or gamma rays to generate pictures of pop over to these guys the weld, exposing inner problems that may not be visible externally. Magnetic particle testing works for detecting surface and near-surface stoppages in ferromagnetic materials, while dye penetrant testing highlights surface area cracks by utilizing a tinted dye

Incorporating these NDT methods right into pipe welding evaluations enhances the accuracy and reliability of weld analyses, making sure that possible failings are identified early. As industries demand greater requirements for safety and efficiency, the function of NDT in preserving the stability of this content bonded frameworks continues to be essential in pipeline construction and maintenance.

Future Fads in Weld Analysis

As we want to the future of weld assessment, advancements in innovation are poised to transform the techniques utilized for evaluating pipeline integrity. The assimilation of expert system (AI) and device learning in assessment procedures is expected to improve the precision of imperfection discovery and predictive upkeep. These technologies enable real-time information evaluation, allowing examiners to identify potential concerns before they escalate into substantial troubles.In addition, using drones furnished with advanced imaging systems is obtaining grip. These aerial assessments can cover large areas rapidly, catching high-resolution photos and information that can be assessed for problems in hard-to-reach locations. This not just enhances safety and security yet likewise boosts performance in the assessment procedure.

Moreover, the growth of smart sensors embedded in pipeline systems offers the possibility for continuous surveillance. These sensors can spot adjustments in stress, temperature level, and resonances, supplying beneficial understandings into the wellness of the welds gradually.

Verdict

In verdict, the integration of sophisticated strategies in pipe welding examination dramatically improves the precision and reliability of weld assessments. Technologies such as automated examination systems, advanced imaging innovations, and non-destructive testing approaches play a crucial role in enhancing issue discovery prices and fostering proactive maintenance approaches. As these innovations remain to progress, they will certainly additionally make sure the safety and effectiveness of pipe systems, eventually adding to the integrity of content essential facilities.

Report this wiki page